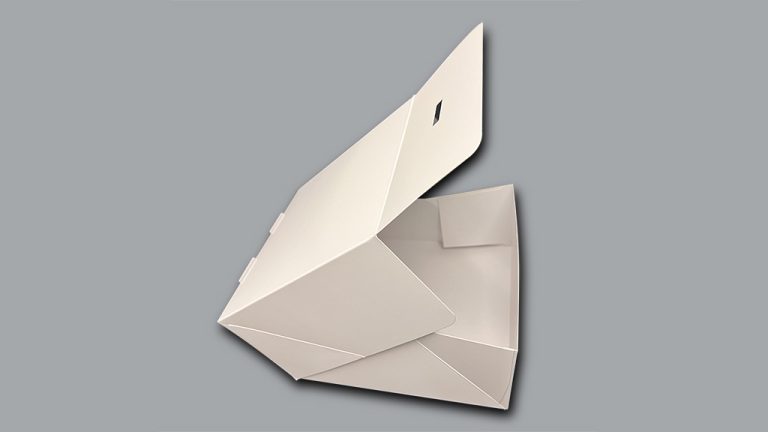

4 and 6-corner gluing is a production process used to create glued trays are a very efficient when it comes to packing – supplied flat, they simply pop open for quick and easy packing.

The corners are glued in one pass on our gluing line – we can provide the whole job including printing and die cutting but we also accept 4 and 6-corner gluing trade work.

We work with a wide variety of different boards and will always help our clients chose the right boards for their products. To keep costs down and to push sustainability we would recommend a white lined chipboard (WLC) this has a minimum of 80% recycled content. It is fully recyclable. It normally has a coated white outside and a light grey uncoated inside. This is normally used where the tray is more practical than for product presentation.

A 4 and 6-corner glued tray can also be made using White Back Folding Box Board (WBFBB). This is also known as GC1. These come is a huge range of weights and finishes and we can choose water resistant and grease resistant coatings to suit different applications. A similar board is a GC2 which has a cream back to the board. Again it comes in a rage of weights and finishes and by it’s nature is slightly cheaper than the GC1.

Careful consideration needs to be given to what will be packed into the trays, the weight, any moisture considerations and how it will be then transported. For best advice, talk to one of our experts today.

We have an eclectic range of clients that use our corner glued trays for all manner of products – chocolates, nuts, cakes, mechanical components, candles and more. We can also supply dividers and inserts to create different sections within the trays. Generally 4 and 6-corner glued trays are only viable for larger quantities where packing time is a primary consideration. They might not be right for you so talk to us and let us explain the options for you.